Recently I spoke with two very large investor owned utilities (IOUs) that are trying to backfill information for thousands and tens-of-thousands of PV systems located in their service territories. In other words, these system planners do not have equipment specifications for distributed energy resources (DERs) on their grids that are worth tens- to hundreds-of-millions of dollars. This is a major concern for system planners as it means that they no longer have an accurate model of their grid.

This is not the first time I’ve had these conversations, and I’m confident it won’t be the last. What strikes me is how preventable this situation is if the business teams running distributed energy resource (DER) and PV interconnection processes understood how important it is to their system planners to collect accurate, detailed PV system specifications.

Clean Power Research recognized years ago that determining the contribution of distributed PV to load shape, peak load reduction, and increased switching of load tap changers and capacitor banks requires accurate behind-the-meter PV system information. The system planners I spoke with have come to the same conclusions, and identified the following information they need to know:

- Which PV capacity interconnection applicants are reporting

- System specifications such as orientation, tilt and shading

- Whether a PV system has been over-paneled relative to inverter capacity

PV capacity, which capacity?

First things first, which PV capacity is your interconnection team collecting? Is it the rated PV capacity of the array of panels? Yes? That’s great! Now, is that the STC rating or the CEC-PTC rating? You’re not sure? Well neither was the applicant who didn’t know which Nameplate Rating was desired when filling out the interconnection application.

Lacking clarity, the applicant simply input the inverter’s AC rating, thinking: “Oh well, it probably doesn’t matter anyway.” And, since there was no visible instruction or option to specify it, they did not mention that the system is over-paneled relative to the inverter capacity.

Are you becoming concerned that the PV capacity data collected during the interconnection process may not be as accurate as you had hoped? You’re not alone.

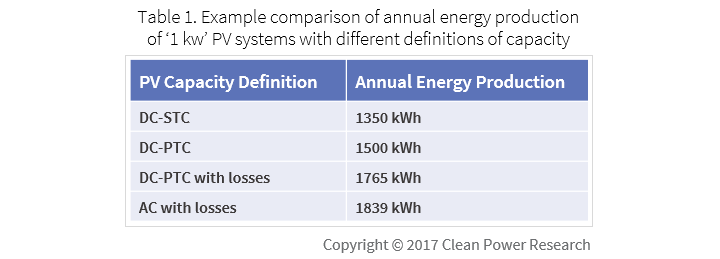

The definition of capacity matters, and it can’t just be swept under the rug. The table below illustrates the difference in annual energy production between 1 kw PV systems with different definitions of capacity.

The reality is that a standard definition of PV capacity does not exist in the industry today. As such, the capacity data that is collected at the time of interconnection has a wide-range of meanings to applicants. To combat this, DER/PV interconnection teams must explicitly specify what information they are looking for and provide handy resources that help confused applicants quickly answer their questions.

Orientation, tilt, and shading

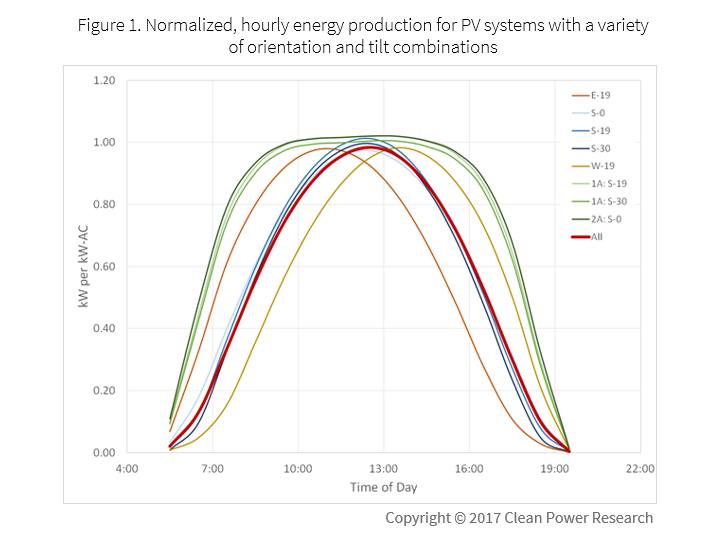

Orientation, tilt and shading have an obvious impact on the daily and seasonal production of a PV system. However, more common than not, DER/PV interconnection teams do not capture this information when first developing their processes because it isn’t deemed necessary for their review process. This hurts their system planning counterparts in a multitude of ways.

For instance, without this information, system planners have difficulty determining the amount of power production they can depend on at a given hour of the day (orientation and shading) during a specific season of the year (tilt and shading), as indicated below in Figure 1.

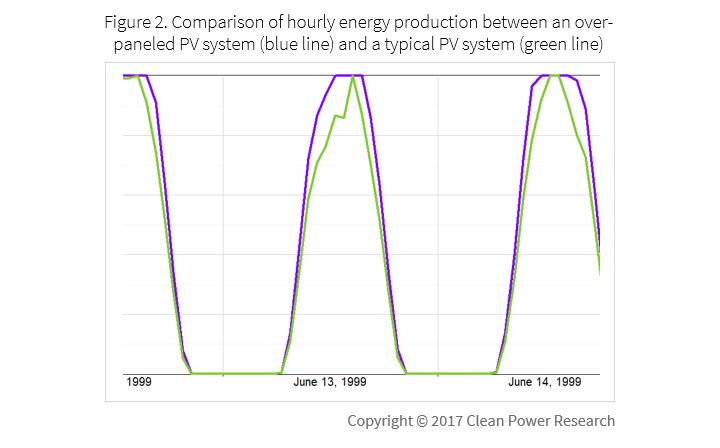

Over-paneling

Over-paneling occurs when developers install a capacity of panels in excess of the inverter capacity. This practice has been growing as panel prices have fallen relatively faster than other installation costs, and as owner/operators have begun to value delivering a more consistent supply of power.

To date, this is predominantly occurring in utility-scale systems, but it’s not hard to imagine a future where customers subject to demand charges begin to over-panel their systems to reduce the variability of their PV production. In many cases, interconnection tariffs prohibit system oversizing, but if you don’t really know what the system size is, how could you effectively enforce the limit?

Planning for the future?

If you’re thinking through these types of issues, we can help. Clean Power Research recognizes the importance of having accurate data for all PV systems—whether they are behind or in front of the meter—to integrate distributed PV with the grid and existing utility planning processes.

For more than 10 years, Clean Power Research has supported integration of PV, starting with PowerClerk®. A powerful and intuitive DER interconnection platform, PowerClerk enables incentive and interconnection applicants to correctly and quickly submit their equipment specifications. PV system specifications collected during the application process are then available to support planning activities down the road. To date, more than 550,000 applications have been submitted through programs offered by nearly 40 utilities and energy agencies using PowerClerk.

Our SolarAnywhere® Data and FleetView® products allow utilities to model the production of their PV fleets for either a typical year or actual years from 1998 through the present. The most accurate modeling uses actual PV system specification data that is (you guessed it!) captured in PowerClerk. Our Consulting team also supports system planners by performing customized studies of distributed energy resources, developing load shaping strategies and delivering forecasts of customer adoption.

To learn more about how PowerClerk can streamline interconnection—including facilitating the capture of accurate specification data—feel free to Contact Us!